Additional air suspension

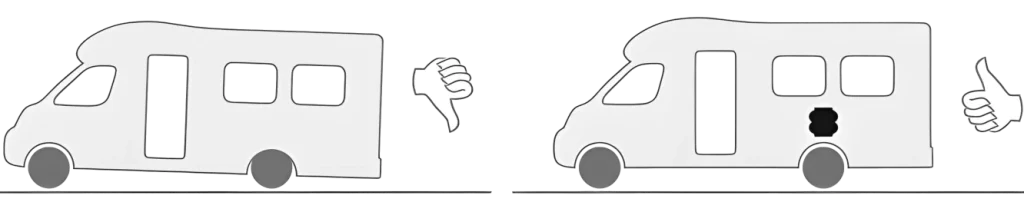

Motorhomes and commercial vehicles face a number of design challenges: constant load with rapidly changing load distribution, heavy equipment and heavy machinery. Standard steel springs quickly reach their limits. Their main drawback is that they lose tension under constant load and the chassis no longer performs as expected. If a brand-new vehicle is still running reasonably well, ageing steel springs are often the cause of a significant loss of ride comfort and safety after only a few months. Steel spring fatigue also causes the vehicle to literally sag at the rear axle, meaning that the original spring work can no longer be performed. Auxiliary air springs can help. They raise the rear of your car and provide a much more comfortable ride.

With auxiliary air springs, the air bellows are placed next to or on top of the existing steel rear springs, reducing the load on the springs. Auxiliary air suspension allows the vehicle to be raised to the desired height and provides a more comfortable ride when loaded. Depending on the type of vehicle, the additional air suspension can also increase the GVWR.

The suspension is manually controlled from a cab mounted panel which includes a button to start the compressor which simultaneously fills the bellows, two bleed buttons to control the bellows separately and two pressure gauges.

Additional air suspensions are available for most light trucks, motorhomes (AL-KO and conventional chassis) and pick-ups, and include all necessary documentation for type approval.